Könnyű, merev bőrökHajlamos a delaminációra, korlátozott UV-élettartamBeltéri jelzések, kijelzők, válaszfalakCeluka PVCSűrű, zárt cellás, rendkívül tartósMagasabb költségek, kevésbé rugalmasKültéri bútorok, hajózási alkalmazások, burkolatokEsettanulmány: Kültéri jelzések Florida partvidékénEgy 2019-es tanulmány összehasonlította a következők teljesítményét:

Celuka PVC

és szabványos

habmagos PVC lemezek Miami párás, sós környezetében. Öt év alatt:A Celuka panelek eredeti szilárdságuk 92%-át megtartották, és nem mutattak látható degradációt.A habmagos lapok szélein delamináció és felületi repedések alakultak ki, ami négy év után cserét igényelt.A tanulmány a Celuka kiváló teljesítményét a zárt cellás szerkezetének és az UV-sugárzásnak ellenálló bevonatainak tulajdonította, amelyek megakadályozták a sósvíz és az UV-sugárzás behatolását.KövetkeztetésA PVC habpanelek élettartama az anyagtudomány, a környezeti ellenálló képesség és a felhasználói gondosság függvénye. Integrált hab PVC és Celuka PVC a tartósság és a sokoldalúság legjobb egyensúlyát kínálják, optimális körülmények között több mint két évtizedes élettartammal. Habmagos PVC lemezekköltséghatékony megoldásokat kínál beltéri használatra, miközben

Lowes PVC hablemez Ideiglenes vagy alacsony igénybevételű alkalmazásokhoz alkalmas. Az UV-stabilizált, nagy sűrűségű változatok kiválasztásával és a megfelelő telepítési és karbantartási protokollok betartásával a felhasználók maximalizálhatják a panelek élettartamát a különböző éghajlati viszonyokban és felhasználási módokban. Ahogy a fenntartható, tartós anyagok iránti kereslet növekszik, a PVC habtechnológia fejlesztései – mint például a bioalapú gyanták és az öngyógyító bevonatok – ígéretet tesznek arra, hogy az elkövetkező évtizedekben tovább meghosszabbítják ezeknek a paneleknek az élettartamát. and standard expanded PVC variants, lacking advanced UV stabilizers, typically degrade within 5–8 years under direct sunlight. In contrast, Celuka PVC and foam core PVC sheets treated with UV-resistant coatings can endure 15–20 years in sheltered outdoor environments, such as under awnings or in covered walkways. However, lowes pvc foam board panels installed in coastal or industrial zones—where salt, pollutants, and high humidity accelerate corrosion—may require replacement after 5–10 years, even with protective treatments.

Comparative studies on PVC pipes (a related material) suggest that properly manufactured PVC can theoretically last 100+ years underground, as stable temperatures and limited oxygen exposure slow degradation. Surface-exposed panels, however, face constant environmental stress, leading to faster aging. For example, a 2018 industry report found that uncoated PVC signage in sunny climates lost 30% of its tensile strength within five years, while coated variants retained 85% of their original strength over the same period lowes pvc foam board.

Key Factors Affecting Longevity

1. Material Quality and Manufacturing Process

The durability of PVC foam panels hinges on their cellular structure, resin composition, and additives.

Integral Foam PVC: Produced via a controlled extrusion process, this variant features a uniform distribution of closed cells, balancing strength and flexibility. Its homogeneous structure resists delamination and stress fractures, making it suitable for thermoforming applications like curved signage or furniture components lowes pvc foam board.

Celuka PVC: Manufactured using a high-pressure molding technique, Celuka boards develop a dense, closed-cell core with a rigid outer layer. This structure enhances impact resistance and water repellency, ideal for outdoor furniture or marine installations. Tests show Celuka panels absorb 90% less moisture than standard expanded PVC, reducing the risk of mold and swelling.

Foam Core PVC Sheets: These consist of a lightweight foam center sandwiched between two thin PVC skins. While cost-effective, their layered construction is prone to edge delamination if cut improperly or exposed to mechanical stress. UV-stabilized skins can extend outdoor life by 5–10 years.

Lowes PVC Foam Board: Often a generic term for standard expanded PVC, this material has larger, irregular cells that compromise strength and moisture resistance. It is best suited for short-term indoor projects or applications where cost outweighs longevity concerns.

2. Environmental Exposure

UV Radiation: Prolonged sunlight exposure triggers photodegradation, breaking down polymer chains and causing yellowing, brittleness, and surface cracking. Foam core PVC sheets with acrylic or polycarbonate overlays resist UV damage better than untreated panels. In regions with intense sunlight, such as Arizona or Australia, unprotected PVC signage may require replacement every 3–5 years.

Temperature Extremes: High heat accelerates oxidation, while freezing conditions can cause contraction and cracking. Integral foam PVC with thermal stabilizers maintains flexibility in temperatures ranging from -40°C to 80°C, whereas standard PVC becomes brittle below 0°C.

Moisture and Humidity: Closed-cell structures, like those in Celuka PVC, prevent water absorption, reducing warping and fungal growth. Open-cell variants, common in low-cost Lowes PVC foam board, may swell or delaminate in humid environments, such as bathrooms or basements.

Chemical Exposure: Solvents, acids, and oils can erode PVC surfaces, compromising structural integrity. Panels used in laboratories or industrial settings should be coated with chemical-resistant layers or replaced more frequently.

3. Physical Stress and Handling

Bending PVC Foam Board: Thinner panels (3–5mm) can bend to tight radii (as low as 10mm) without cracking, making them ideal for curved architectural features. However, repeated bending or exceeding the material’s flex limit may cause internal stress fractures. Integral foam PVC with added plasticizers offers greater flexibility than rigid Celuka boards.

Impact Resistance: High-density Celuka PVC resists dents from hail or vandalism better than softer expanded PVC. A 2021 study found that Celuka panels withstood 50 J impacts without cracking, compared to 20 J for standard PVC.

Installation Practices: Improper fastening (e.g., over-tightening screws) or inadequate expansion gaps can lead to stress cracking under thermal movement. Panels installed in areas with significant temperature fluctuations, such as uninsulated roofs, require flexible adhesives and spacing to accommodate expansion.

4. Maintenance Practices

Cleaning: Regular dusting and wiping with mild detergents prevent dirt buildup, which can trap moisture and promote microbial growth. Avoid abrasive cleaners or steel wool, which scratch surfaces and create entry points for contaminants.

Inspections: Annual checks for cracks, discoloration, or edge delamination help identify issues before they escalate. Small cracks can be sealed with PVC-compatible adhesives to extend panel life.

Repairs: Minor damage, such as scratches or dents, can often be sanded and repainted. However, extensive cracking or warping may necessitate full replacement, especially in load-bearing applications.

Comparative Analysis of PVC Foam Types

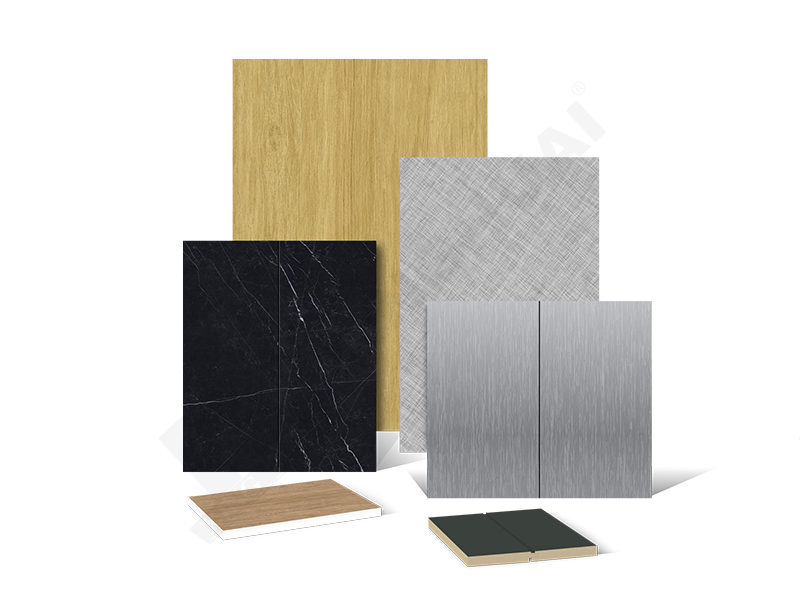

| Material | Key Strengths | Weaknesses | Best Applications |

|---|---|---|---|

| Lowes PVC Foam Board | Cost-effective, easy to cut | Poor UV/moisture resistance, brittle | Short-term indoor projects, crafts |

| Integral Foam PVC | Uniform cell structure, flexible | Moderate cost, less rigid than Celuka | Thermoforming, curved signage, furniture |

| Foam Core PVC Sheet | Lightweight, rigid skins | Prone to delamination, limited UV life | Indoor signage, displays, partitions |

| Celuka PVC | Dense, closed-cell, highly durable | Higher cost, less flexible | Outdoor furniture, marine applications, cladding |

Case Study: Outdoor Signage in Coastal Florida

A 2019 study compared the performance of Celuka PVC and standard foam core PVC sheets in Miami’s humid, saline environment. Over five years:

Celuka panels retained 92% of their original strength and showed no visible degradation.

Foam core sheets developed edge delamination and surface cracking, requiring replacement after four years.

The study attributed Celuka’s superior performance to its closed-cell structure and UV-resistant coatings, which blocked saltwater penetration and UV penetration.

Conclusion

The service life of PVC foam panels is a function of material science, environmental resilience, and user diligence. Integral foam PVC and Celuka PVC offer the best balance of durability and versatility, with lifespans exceeding two decades in optimal conditions. Foam core PVC sheets provide cost-effective solutions for indoor use, while Lowes PVC foam board suits temporary or low-stress applications. By selecting UV-stabilized, high-density variants and adhering to proper installation and maintenance protocols, users can maximize panel longevity across diverse climates and uses. As demand for sustainable, long-lasting materials grows, advancements in PVC foam technology—such as bio-based resins and self-healing coatings—promise to further extend these panels’ service lives in the decades ahead.